by: Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences

As a flexible material with soft and wet properties, polymer hydrogel has been considered as an ideal system for bionic intelligence. But its fragile three-dimensional network structure makes it often lose its use value due to local breakage in its application. In recent years, researchers have prepared a series of polymer hydrogels with self-healing functions by introducing functional groups such as dynamic covalent bonds and supramolecular interactions in the process of gel preparation. However, the existing self-healing hydrogels still have the following limitations: First, the range of the damaged gel should not be too large, and the damaged gel needs to be tightly attached during repair; second, the wound of the damaged gel must be It is fresh, and the healing effect of the gel will be greatly reduced after being left for too long after damage. Therefore, the development of a general and efficient gel repair strategy is of great significance for the development of polymer hydrogels.

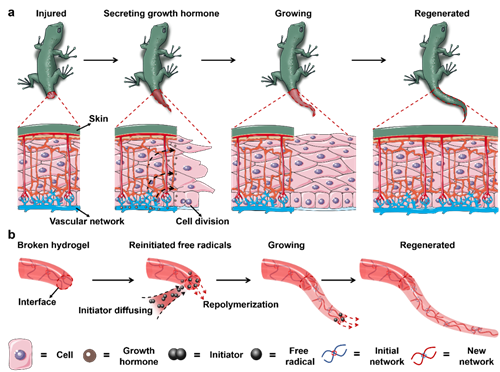

In response to the above problems, the rebirth of the gecko's docked tail provides us with new ideas. When a gecko snaps off its tail to avoid danger, a large amount of growth hormone will be secreted from the wound of the broken tail, which makes the cells at the wound divide and differentiate rapidly, thus gradually growing a new tail at the broken tail (Figure 1a). The intelligent polymer materials team of Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, led by researcher Chen Tao, has been committed to the research of biomimetic intelligent polymer hydrogels (Adv. Mater., 2022, 34, 2107452;Adv. Funct. Mater., 2022, 32, 2108830;Adv. Mater. 2021, 33, 2103937; Angew. Chem. Int. Ed., 2021, 60, 3640; Angew. Chem. Int. Ed., 2021, 60, 8608; Angew. Chem. Int. Ed., 2021, 60, 21890; Mater. Horiz., 2021, 8, 2761;Adv. Funct. Mater. 2021, 31, 2108365; ACS Nano, 2021, 15, 10415; Angew. Chem. Int. Ed. 2020, 59, 19237; Adv. Mater. 2020, 32, 2004290; Research, 2019, 2384347; Adv. Funct. Mater. 2018, 28, 1704568, etc.). Recently, inspired by geckos, the team proposed the method of Interfacial Diffusion Polymerization (IDP) of hydrogels, which realized the macro-precision growth of hydrogels, and further realized the repair of damaged polymer gels.

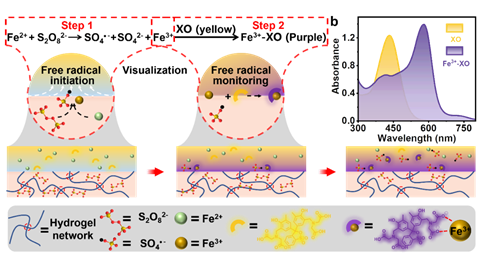

As shown in Figure 1b, the team embedded the oxidative radical initiator ammonium persulfate (APS) into the network of the damaged gel by soaking, followed by the reducing agent tetramethylethylenediamine (TEMED) The hydrogel prepolymer solution is poured on the surface of the damaged gel. Under the action of osmotic pressure, APS will diffuse into the hydrogel prepolymer solution, while TEMED will diffuse into the damaged gel network, and the two will trigger a redox reaction at the interface to generate a large number of free radicals, which will lead to the formation of a large number of free radicals in the damaged gel. Surface polymerization generates new hydrogels, which in turn realizes the repair of damaged gels. In order to further explore the mechanism of this reaction, the team used Fe2+ as a reducing agent, and used the color reaction between xylenol orange and Fe3+ to track and record the generation and diffusion process of free radicals in real time (Fig. 2). By controlling the viscosity of the prepolymerization solution, Delaying free radical diffusion enables uniform and controllable growth of hydrogels. The method using interfacial diffusion polymerization not only enables the growth of new gel networks with high efficiency, but also has extremely high generality. The method of interfacial diffusion polymerization is suitable for growing new hydrogel networks in a series of hydrophilic substrates, and a series of hydrogels with different chemical compositions can also be grown by changing the monomer species in the hydrogel prepolymerization solution. Not only that, by doping different polymer thickeners in the hydrogel prepolymer solution, the newly grown gel can also acquire a series of new functions. For example, when sodium alginate is used as a thickener, the grown gel can be complexed with Ca2+ to realize the shape memory function of the hydrogel. When a polymer with blue fluorescence is used as a thickener, the grown gel can also obtain corresponding fluorescence emission function.

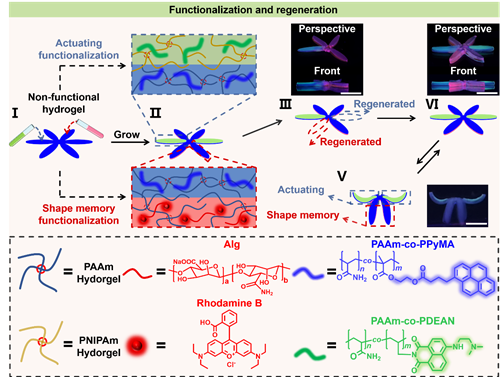

Benefiting from the high efficiency and universality of the IDP method, the team realized the customized repair of the damaged polymer hydrogel. As shown in Figure 3, two claws in a six-claw-like polyacrylamide/poly-N-isopropylacrylamide (PAAm/PNIPAm) bilayer gel were broken during use. Using the method of IDP, the team first used a prepolymer solution containing acrylamide monomer to grow the first layer of PAAm gel at the damaged position, and then switched to a prepolymer solution containing N-isopropylacrylamide monomer in The PNIPAm layer gel was grown on the basis of the first layer, so as to realize the repair of the damaged gel, and compared with the gel before the damage, the chemical composition, physical structure and deformation function of the repaired gel were restored to the original state. undamaged state.

This work was recently published in CCS Chemistry (2022, DOI: 10.31635/ccschem.022.202201942) in a paper titled "Interfacial Re-initiation of Free Radicals Enables the Reborn of Broken Polymeric Hydrogel Actuators". This work was supported by the National Natural Science Foundation of China (51873223, 52073295), the Key Research Program of Frontier Science of the Chinese Academy of Sciences (QYZDB-SSW-SLH036), the Sino-German Cooperation International Exchange Program (M-0424) and the Wang Kuancheng Education Foundation (GJTD-2019-13) and other project support.

Figure 1. Gel repair and regeneration strategy based on free radical interfacial diffusion inspired by the rebirth of gecko tail

Figure 2 Real-time monitoring strategy of interface diffusion aggregation

Figure 3 Functional repair and regeneration of hydrogels

(Figure by: Wu Baoyi, Polymer Laboratory)

Source: http://nimte.cas.cn/news/progress/202204/t20220412_6425179.html

Disclaimer: This article is translated by cpolymer. The translation is for reference only. All contents are subject to the original text.